Waterproofing

Water leaks and elevated moisture in garage decks caused by a lack of an effective waterproof membrane can be devastating to a parking garage structure. Water penetration through the deck surface can result in concrete spalling from freeze thaw cycles and rusting of reinforcement and structural steel components. This could compromise the structural load carrying capacity of the parking garage significantly and create a dangerous condition. Consequences can range from falling pieces of concrete to catastrophic failure so it is imperative to properly protect the garage deck.

Concrete garage waterproofing systems typically fall into two general categories; traffic wearing exposed waterproofing membranes and sandwiched between the slab waterproofing membranes.

Traffic wearing waterproofing membranes; these membranes are applied to the topmost surface of the parking deck and remain exposed. They provide waterproofing protection while resisting vehicular traffic and the associated fluids, snow plows and the elements including ice, rain, salt and ultra-violet light. Membranes typically could be comprised of polyurethane, epoxy, acrylic, silane or a combination of these materials. Some characteristics of the system that are considered are; the ability survives abrasion, adhesion and anti-skid qualities and sufficient flexibility to expand and contract without failing. Although these systems can provide years of protection it is recommended that they are periodically maintained to prolong its life.

The benefit of these membranes is that the waterproofing protection is not concealed and can be properly inspected and even restored.

Our Services Provided:

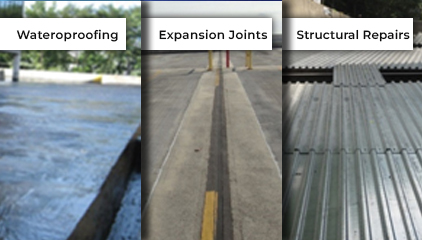

- Waterproofing

- Expansion

- Joints and Joints Structural Repairs

- Engineering

Sandwich slab waterproofing membranes; these membranes are typically installed between the structural deck and a traffic wearing surfacing such as asphalt or concrete and do not remain exposed. The traffic wearing surface material is subjected to the outside elements while protecting to the waterproofing membrane so it tends to survive a longer period of time without requiring maintenance. Sandwich slab waterproofing membranes are typically comprised of liquid applied polyurethane, modified bitumen sheathing, or hot asphalt. A protection barrier is installed over the membrane surface to protect it from damage while the wearing material (i.e. asphalt) is installed. Specific drain grates are required to discharge the water from the membrane surface as well as the traffic wearing surface and a drainage stratum is typically included in the design.

Though these waterproofing membranes are protected by a wearing material, they cannot be inspected. Additionally, the wearing material (often termed over-burden) must be completely removed in order to reveal and restore/replace the waterproofing material. This is a far greater expense than the traffic wearing waterproofing membranes.